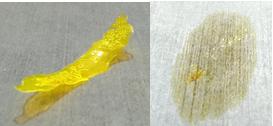

A polymer that self-destructs? While once a fictional idea, new polymers now exist that are rugged enough to ferry packages or sensors into hostile territory and vaporize immediately upon a military mission’s completion. The material has been made into a rigid-winged glider and a nylon-like parachute fabric for airborne delivery across distances of a hundred miles or more. It could also be used someday in building materials or environmental sensors.

The researchers will present their results today at the American Chemical Society (ACS) Fall 2019 National Meeting & Exposition. ACS, the world’s largest scientific society, is holding the meeting here through Thursday. It features more than 9,500 presentations on a wide range of science topics.

https://www.youtube.com/watch?v=A7QXerW77I4

“This is not the kind of thing that slowly degrades over a year, like the biodegradable plastics that consumers might be familiar with,” says Paul Kohl, Ph.D., whose team developed the material. “This polymer disappears in an instant when you push a button to trigger an internal mechanism or the sun hits it.”

The disappearing polymers were developed for the Department of Defense, which is interested in deploying electronic sensors and delivery vehicles that leave no trace of their existence after use, thus avoiding discovery and alleviating the need for device recovery.

[ad_336]

The key to making a polymer disappear, or break apart, is “ceiling temperature.” Below the ceiling temperature, a polymer configuration is favored, but above that temperature, the polymer will break apart into its component monomers. Common polymers, like polystyrene, have a ceiling temperature above ambient temperature and are very stable. And even when they are warmed above their ceiling temperature, some of these materials can take a long time to decompose. For example, thousands of chemical bonds link all of the monomers together in polystyrene, and all of these bonds must be broken for the materials to decompose. But with low ceiling-temperature polymers, such as the cyclic ones Kohl is using, only one bond needs to break, and then all of the other bonds come apart, so the depolymerization happens quickly. The process can be initiated by a temperature spike from an outside or embedded source, or by a light-sensitive catalyst.

For many years, researchers have attempted to make these polymers, but were unsuccessful because of the materials’ instability at room temperature. Kohl’s research group at the Georgia Institute of Technology discovered that they could overcome this issue if they were careful to remove all impurities formed during the synthesis. In addition, they found a number of aldehydes, including phthalaldehyde, that readily form cyclic polymers. Once they had optimized this polymer’s synthesis, they focused on ways to make it disappear.

To do this, the researchers incorporated into the polymer a photosensitive additive, which absorbs light and catalyzes depolymerization. “Initially, we made it photosensitive to just ultraviolet light so we could make the parts in a well-lit room with fluorescent lighting, and it was just fine; it was stable,” Kohl says. But when the polymer was placed outside, exposure to sunlight vaporized it (or reverted it back to a liquid, in some cases). A vehicle deployed at night would, therefore, disappear with the sunrise.

[rand_post]

Kohl’s group has since discovered new additives that can trigger depolymerization at different wavelengths of visible light, so the polymer can decompose indoors.

“We have polymers designed for applications in which you come in the room, you turn the light on, and the thing disappears,” Kohl says.

The group has also determined how to stall depolymerization. “We have a way to delay the depolymerization for a specific amount of time – one hour, two hours, three hours,” he says. “You would keep it in the dark until you were going to use it, but then you would deploy it during the day, and you would have three hours before it decomposes.” The team has considered chemical methods to start the decomposition process, as well. In addition, they are testing various copolymers that can be added to phthalaldehyde to change the material’s properties without altering its ability to vanish.

Kohl says that this “James Bond”-like material is already being incorporated in military devices by other researchers. But he also sees the potential of the materials for non-military applications. For example, the researchers have made a disappearing epoxy for a temporary adhesive that could be used in building materials. They also imagine the material could be used as sensors for environmental monitoring. Once the sensors are finished collecting data, there is no risk of littering the environment since they can be triggered to vaporize. The material can also be used for delivery vehicles in remote areas where recovery is difficult.