Japanese researchers were able to rapidly and accurately predict the microstructure of Nickel – Aluminum (Ni-Al) alloys that are commonly used in the design of jet engine turbine parts. Predictions of the microstructure of these alloys have so far been time-consuming and expensive. The findings have the potential to greatly advance the design of materials – made up of a range of different alloys – that are used to make products in several different industry sectors.

Alloys are durable materials made up of two or more metals. The current high cost and design limitations of traditional alloy manufacturing processes have driven the need to create more efficient design methods. One key challenge has been how to accurately predict an alloy’s microstructure (the very small-scale structure that is only visible by microscope) which can greatly influence physical properties such as strength, toughness, resistance to corrosion, hardness and/or wear and tear resistance.

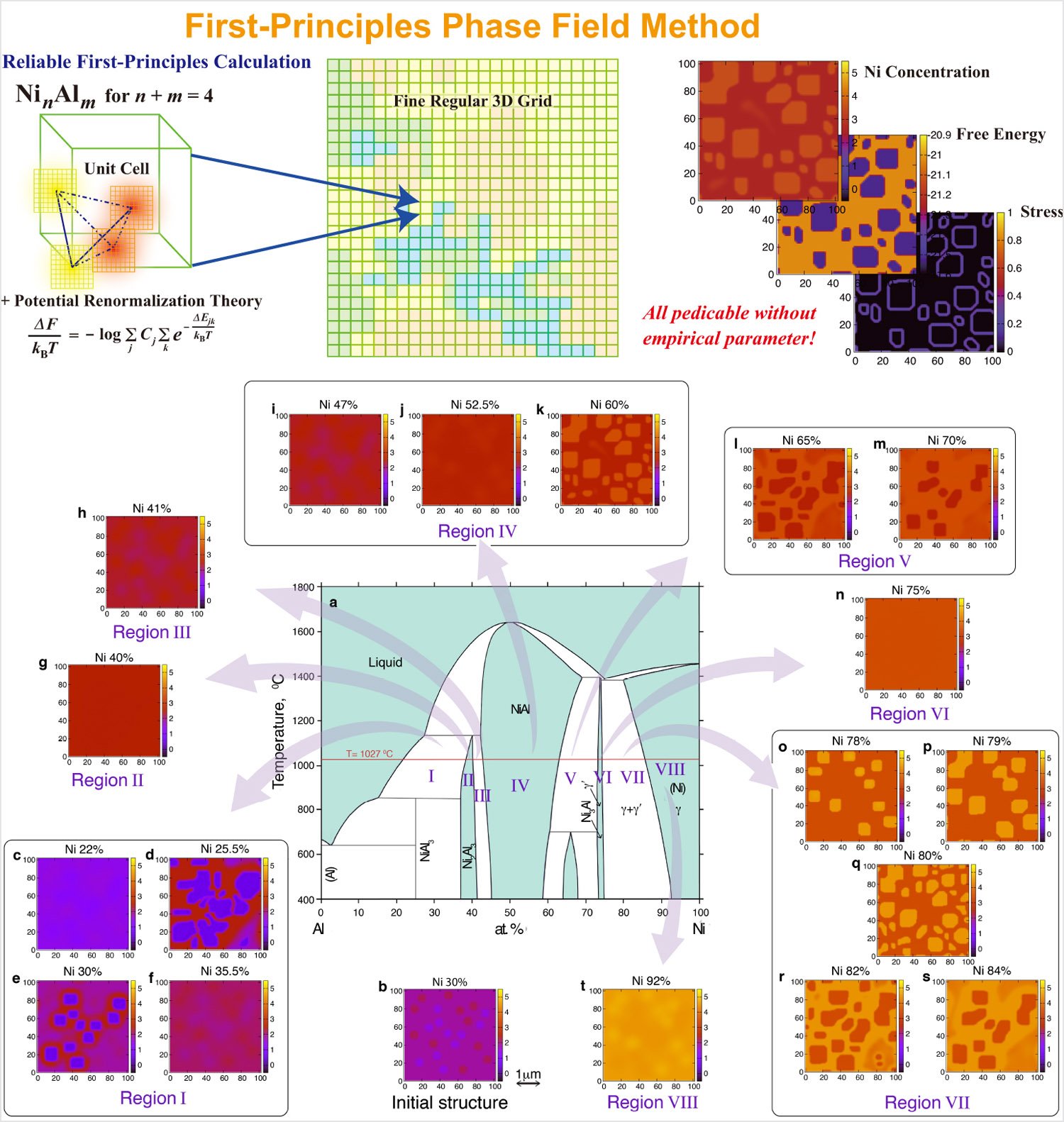

The authors were able to predict alloy microstructures by using the “first-principle phase field method.” This procedure predicts the microstructure of alloys based on the fundamental laws of physics alone (first principles) and then uses those parameters to model microstructure formations (phase field). This is contrary to empirical modeling, or predictions based on experiments or previous observations alone. Furthermore, the researchers conducted their modelling experiments under high temperatures that mimic those of jet engine turbines (~1027oC).

The research was published in Nature Communications on Aug 1, 2019.

The quest of new materials with desirable properties requires microstructure engineering of materials based on changing several variables, such as composition, morphology, pressure, temperature, doping, casting and forging.

[ad_336]

A reliable simulation technique that can help with the design and production of new materials based on a theoretical principle alone could make production faster and cheaper. However, most of the current theories of material design are phenomenological and derived from experimental observations and empirical experiences. These are both time-consuming and expensive.

What makes the first-principles phase field method so advantageous, according to the authors, is that it bridges the accurate small-scale (first principles) calculations and large-scale (phase field) model by renormalization theory, a concept in physics that essentially makes infinite degrees of freedom finite, or continuous variables discrete. In other words, by using their method, they were able to overcome time-consuming and expensive experimental procedures and still produce materials that were in agreement with experimental methods.

“First-principles phase field method was invented as the world’s first innovative multiscale simulation technique. Using this method, we were able to successfully predict complex microstructures of any compositions of Ni-Al alloys from first-principles (basic laws of physics) without using any empirical parameter, and our results agree quite well with experiments,” says Kaoru Ohno, corresponding author and professor at Yokohama National University.

Ohno and co-authors from the National Institute for Materials Science in Japan say the method can be used to predict mechanical strength of alloys because the local force distributions as well as the microstructures can be easily calculated.

[rand_post]

The method that the authors present can also be used to predict microstructures of multicomponent alloys, or alloys that are made up of more than two metals. “These studies highlight the fundamental nature of steels and other alloys that have so far only been demonstrated based on empirical observations. As such, the proposed method is a powerful theoretical tool to quickly predict the most suitable alloy that can realize the desired strength, toughness, ductility, plasticity, lightness, etc. as much as possible,” adds Ohno.

In the future, the authors plan to apply the method to various steel materials and other multicomponent alloys in order to predict the dependence of microstructures and local stress distributions on their initial compositions and better understand their characteristics.